pW-petersWorkshop

This is where my electronic systems come to life.

As a working musician and sound engineer, I build and test everything right here – with real-world needs in mind. Whether it's live theatre, studio setups, or touring rigs, pW systems are built for reliability, flexibility, and musicality.

What I create:

Custom Changeover Controllers (COC) for redundant audio & MIDI setups

Rack systems with switchable Macs, soundcards, KVM, MIDI routing

Self-designed PCBs (manufactured in China)

Hardware/software hybrids (in collaboration with KeyComp)

Custom instrument interfaces for professional musical productions

All builds are tested in real shows – nothing leaves the workshop unless it works under pressure.

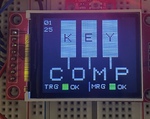

BlueLine 2.0 — Real-Time Module Status Monitoring

The new BlueLine 2.0 prototype introduces a fully integrated real-time status display for both internal microcontroller modules.

The TFT screen now communicates directly with the Trigger Interface (TRG) and the MIDI Merger (MRG), each driven by an independent AVR32SD28.

A lightweight heartbeat protocol ensures that the display continuously monitors both subsystems.

Every module sends a short digital pulse to the Curiosity Nano (display controller), which evaluates the signal several times per second.

-

TRG = Trigger Interface

-

MRG = MIDI Merger

-

Green “OK” indicator = Module alive and responding

-

Red “ERR” indicator = No heartbeat / module failure detected

This provides immediate visual feedback about system health without requiring any external tools.

Compared to earlier test versions, the red debug frame around the graphics has been removed, giving the display a cleaner and more professional look.

The communication link is intentionally simple and electrically isolated, ensuring stability even in demanding live environments.

For BlueLine 2.1, the internal communication is planned to be upgraded to I²C, enabling richer diagnostics and bidirectional control between modules.

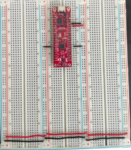

New MIDI_Merger – Compact, Fast, and Reliable

The new MIDI_Merger replaces our previous relay-based MIDI switch system.

Instead of mechanical switching, it uses a fully electronic changeover controller powered by the AVR32SD28microcontroller — ensuring lightning-fast performance and outstanding reliability.

The breadboard prototype is running smoothly, and the PCB is ready for production.

With this design, MIDI routing becomes silent, precise, and maintenance-free, even under heavy use.

Soon to be integrated into the Keycomp setup – a major step forward in digital signal control.

New MADI_Switch – Ready for Action Soon!

Our new MADI Bridge Switch is designed to replace the existing MIDI Solutions box.

At its core runs a highly reliable AVR32SD28 microcontroller, ensuring fast, clean, and rock-solid switching performance.

The breadboard prototype is already stable, and the PCB design is finalized — compact, durable.

This means future MADI switching will be silent, wear-free, and ultra-reliable.

Next step: real-world testing in the Keycomp system.

Powered by the new AVR32SD32 from Microchip

At the heart of the unit is the Microchip AVR32SD32 microcontroller, providing fast and stable performance for real-time MIDI processing. This powerful platform allows seamless handling of standard MIDI commands as well as System Exclusive (SysEx) messages for advanced device configuration.

Key Features

-

Automatic & Manual Changeover

Instantly switches between two independent audio or MIDI signal paths – ideal for redundant live setups.

-

Full MIDI Integration

Supports standard MIDI protocol and advanced SysEx control, enabling deep integration with modern gear.

-

Hands-Free Operation

A dedicated footswitch input lets you control changeover and MIDI functions on stage without interrupting your performance.

-

Reliable Hardware Design

Built with robust electronics and housed in a durable metal chassis, ready for demanding touring conditions.

Benefits

-

Rock-solid reliability with dual-path redundancy

-

Advanced MIDI control thanks to SysEx support

-

Performer-friendly workflow with footswitch operation

-

Future-proof platform based on the latest AVR32SD32 microcontroller

Whether on stage or in the studio, the MIDI Changeover Controller ensures your setup keeps running smoothly – even when the unexpected happens.

New KeyComp Prodigy PCB in Production

We’re excited to share a major milestone from our workshop: the new KeyComp Prodigy 007.1 PCB has arrived and is now being assembled into eight fully functional Control Output Controllers (COCs).

Designed in-house and manufactured in collaboration with Elecrow, this board is built around the Raspberry Pi Pico and features latching relays for secure and power-efficient switching. Each board is carefully assembled, tested, and integrated into professional-grade housings, ready for real-world applications.

Key Features

pW–2025.05 Prodigy 007.1 PCB (design by pw-Werkstatt)

4 latching relays for stable state switching without constant current

Integrated display module for status feedback

Clean, modular wiring with Neutrik and D-Sub connectors

Dual power input for redundancy in live setups

Applications

MIDI control and automation

GP (General Purpose) switching in theater, touring, and studio setups

Every detail – from PCB soldering to cable harnesses – is handmade with precision. We’re proud to be building robust tools that meet the demands of professional stage and AV environments.

New PCB – pW_2025.05 „Prodigy 007.1“

Fresh from the factory – and now fully assembled and tested in pW – petersWorkshop.

This board features:

-

Latching relays for passive failover switching

-

A compact controller core based on a Pi Pico

-

Modular I/O with OLED status screen

-

Designed for integration in live music environments and touring racks

Originally designed for internal use with KeyComp systems, it’s now entering real-world testing – and showing solid first results.

? Manufactured in China

? Assembled + verified in Hamburg

? peterspeter@icloud.com

Built to survive the pit. And the road.

New product is leaving our harbour

Another full performance system, custom-built in pW – petersWorkshop, is now on its way to the U.S. tour of Beauty and the Beast.

Featuring redundant Macs, MIDI control, audio interfaces, keyboard integration and live switching – stage-ready and road-tested.

April 2025 – PCB is back and ready to go

Fresh from the fab – the new board is here.

A clean red layout, clear silkscreen, and first power-on with LED confirmation.

This one will handle power management, digital control and expansion ports – part of an ongoing modular project in pW – petersWorkshop.

Next step:

Bestücken – or in international terms: component party time.

April 2025 – New PCB shipped!

Today we shipped out a freshly developed PCB from pW – petersWorkshop.

This board is part of a new switching system for live audio setups, offering ultra-fast and fail-safe changeovers between redundant sources.

Each board is hand-tested in my workshop and part of a growing toolkit built for theatre, touring, and live performance reliability.

Let’s call it:

„The smallest crew member with the biggest responsibility.”

January 2025 – Internal Test Build @ pW

This PCB is part of an internal development series for a modular live control system.

It combines MIDI routing, switch control, KVM relays, and failover logic – all designed to interface directly with Arduino-based automation in a live setup.

The build was designed, routed, and tested in pW – petersWorkshop as part of a broader R&D effort for future live redundancy systems.